Machine Vision Technology and Robot Guidance

IHFood is a multidisciplinary company employing a wide range of technologies. Our aim is to assist or replace human inspection of organic material where it makes sense. Our engineering team consists of experienced developers with backgrounds in optics and light, image acquisition, electrical engineering, software development, robotics and machine learning.

Image Acquisition

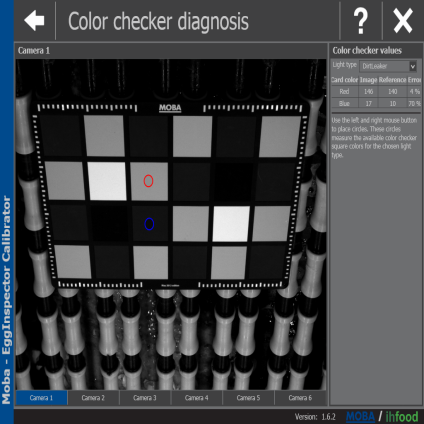

We apply multispectral imaging to enable differentiation of flaws in the complex diversity that is present in organic samples. Great effort is put into optimizing lighting geometry and selecting the right spectral bands in order to have the best data available for the following analysis.

As the inspection is inline and at high speed we utilize advanced synchronization, buffered burst imaging and fast high-power current-controlled lighting. Finally, the technical advances in sensors, cameras and interfaces are followed closely and consistently applied in the quest for higher speed.

Electronics

To be able to precisely control the timing of the different parts in our highly customized vision systems, we use both off-the-shelf components and customized PCB designs. Off-the-shelf components include timing and light controllers built for machine vision systems. Customized PCB designs range from simple input/output circuits and LED drivers to custom shields with custom micro controller firmware to achieve the micro second precision needed for inspecting products continuously moving on e.g. a conveyor belt.

Software

At the heart of our vision systems is the application software, which often runs 24/7 at our end-customers without interruption, in many cases for +5 years without ever being restarted. To ensure the stability and robustness of our applications we use modern development methodologies such as Test Driven Development and Continuous Integration; with automatic testing ranging from small unit tests to full end-to-end tests.

We focus on our customers needs using agile processes e.g. Scrum or Kanban to be able to deliver value as soon as possible. Development is done primarily in C# and C++ employing the latest tools and services. Our applications have handled billions of images over their lifetime providing actionable analysis results in real-time inline at our end-customers production facilities.

Image Analysis & Machine Learning

Inspecting organic material requires our vision systems to cope with a large amount of natural variation. To capture this variation, and provide measurements with state-of-the-art precision, we employ the latest methods in machine learning and image processing. This includes a wide range of machine learning algorithms ranging from regression to ensemble methods and deep learning.

We use a data driven approach working with millions of images and iteratively lower the error rate of our machine learning models. We continuously automate this process to cope with the ever-increasing amounts of data.

Robotics

We also control real-world robots on the basis of our vision system results. Based on online 3D scanning of each individual product, we are able to calculate tailor-made, high precision toolpaths, which optimizes cutting of e.g. meat by locating bones and joints. Our software can then control a robot arm for processing of food at production line speeds.

Our approach does not need special mechanical solutions for retaining of the products, but locates and processes the products in real time, directly on the conveyor line.